-

“Advantages of Dual Plate Check Valves: Lightweight, Non-Slam, and High-Pressure Capacity”

Dual Plate Check Valves are non-return valves used in various industries to prevent backflow and ensure pipeline system safety. They offer several advantages, including low-pressure drop, non-slam design, and high-pressure capacity. In this article, we explore the features and benefits of Dual Plate Check Valves. Lightweight Design Dual Plate Check Valves are significantly lighter and…

2023-03-12 -

The Advantages of Pressure Seal Valves in High-Pressure Systems: A Comprehensive Guide

Pressure seal valves are widely used in power generation and refinery applications, where high-pressure systems require reliable and efficient sealing mechanisms. These valves offer several advantages over conventional bolted body-to-bonnet sealing mechanisms, including reduced maintenance requirements and improved safety. In this blog post, we will discuss the workings of pressure seal valves, their different types,…

2023-03-11 -

A Lift Check Valve and Its Applications

A lift check valve is a type of non-return valve that prevents the backflow of media in piping systems. It is constructed using materials such as metal, plastic, or stainless steel and functions to stop media from backing up into the chamber. In this blog post, we will discuss the definition, applications, and benefits of…

2023-03-11 -

What Are the Differences Between Socket Welds and Butt Welds?

When it comes to joining pipes, two of the most popular welding techniques are socket welding and butt welding. Both methods are effective in connecting pipes, but they have some key differences. In this blog post, we will discuss the differences between socket welds and butt welds to help you make informed decisions for your…

2023-03-10 -

How Swing Check Valves are Tested and Inspected: A Comprehensive Guide

Swing-type check valves are widely used in wastewater, water, and industrial fluids applications to control fluid flow. They have a hinged disc that swings open and closed under pressure. These valves are commonly used for fluids with particles and come in metal-to-metal or resilient seated designs. However, they are not designed to handle pulsating or…

2023-03-09 -

Socket Welding Check Valves: A Comprehensive Guide

Socket welding check valves play a critical role in various industrial settings, including power generation and commercial construction. They are designed to prevent backflow and ensure the integrity of high-pressure systems. However, with the numerous socket weld fittings available in the market, it can be challenging to choose the right valve. In this guide, we…

2023-03-09 -

Everything You Need to Know About Globe Valves: Types, Parts, and Working Principles

This article covers everything you need to know about globe valves, including their types, parts, and working principles. We also provide tips on selecting the ideal globe valve based on factors like material, size, and pressure limits. Globe valves are regulating or shutoff valves used to control liquid flow in various applications. They come in…

2023-03-08 -

Understanding the Industrial Applications of Socket Welding Check Valves

Socket welding check valves play a critical role in a variety of industrial applications, ranging from the oil and gas industry to water supply, power generation, petrochemicals, and chemical admixtures. These valves are designed to prevent backflow in piping systems and are engineered to withstand extremely high pressures and temperatures. Given the importance of these…

2023-03-08 -

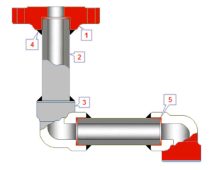

Each Part of the Valve

Valves are essential components in controlling the flow of fluids and gases in different industrial applications. The different types of valves have specific parts that make them unique. One of the most critical factors that determine the effectiveness of a valve is the material used to make its sealing surface. This blog post discusses the…

2023-03-08 -

Materials selected for each part of the valve

The materials used for each part of the valve play a crucial role in determining the longevity and effectiveness of the valve. Here are the recommended materials for each part: Valve body: The valve body should be mainly made of ductile iron. The grade and actual physical and chemical test data of the cast iron…

2023-03-07 -

The Selection Principle Of The Globe Valve

Introduction Globe valves are commonly used in various industries because of their reliability and versatility. The stem axis of the globe valve is perpendicular to the seating seal surface, and its valve stem opening or closing stroke is relatively short. Globe valves are mostly used as a medium for cutting or regulating and throttling use.…

2023-03-07 -

What Are The Problems With Installing Stainless Steel Ball Valves?

Stainless steel ball valves are widely used in different industries as they are suitable for various working mediums, including corrosive media. However, installing stainless steel ball valves can be tricky,…2023-03-06