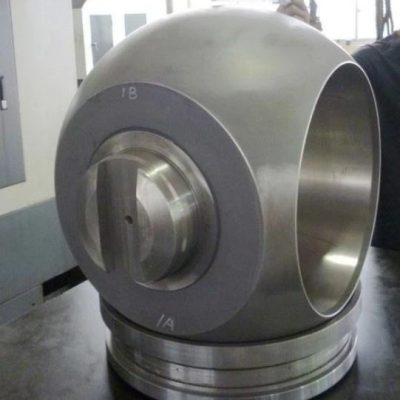

Metal Seated Ball Valve

Metal Seated Ball Valve is a valve that has two structures, floating ball, and fixed ball. The metal seat ring is in contact with the spherical surface, and the seat ring and the spherical surface form a seal through the uniform spring load acting on the seat ring. The valve is generally installed in the diameter direction of the pipeline, and when the valve plate rotates to 90°, the valve is fully opened. The main material is metal, which is precision-processed and has an exquisite appearance without burrs.

Technical Specifications:

| Specification | Description |

|---|---|

| Sizes | NPS 2 to NPS 48 |

| Pressure Class | 150 to 2500 |

| Forged Materials | A105, A182 F304, F304L, F316, F316L, F51, F53, A350 LF2, LF3, LF5 |

| Casting Materials | A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2 |

| Other Materials | Monel, Inconel, Hastelloy |

| Bore | Full or Reduced |

| Connection | RF, RTJ, or BW |

| Entry Design | Side or top |

| DBB | Double Block & Bleed (DBB),Double Isolation & Bleed (DIB) |

| Seat Injection | Emergency seat and stem injection |

| Anti-Static | Anti-Static Device |

| Anti-Blow out | Anti-Blow out Stem |

Design Standard

Design & manufacture according to API 6D, API 608, ISO 17292

Face-to-face according to API 6D, ASME B16.10

End Connection according to ASME B16.5, ASME B16.47, MSS SP-44 (NPS 22 Only)

Test & inspection according to API 6D, API 598

Fire safe design according to API 6FA, API 607

Also available per NACE MR-0175, NACE MR-0103, ISO 15848

Coatings:

- Nitridation

- Tungsten Carbide

- Spray Stellite

- Spray Nickel Alloy

- Spray Cobalt Alloy Etc.

Advantages of Metal Seated Ball Valve

Metal-seated ball valves offer a number of advantages over other types of valves, including high temperature and pressure resistance, long service life, and excellent sealing performance. They are also less prone to leakage and require less maintenance than other types of valves. Metal-seated ball valves are ideal for use in harsh and abrasive environments, where reliability and durability are critical.

Applications of Metal Seated Ball Valve

Metal-seated ball valves are used in a wide range of applications, including oil and gas processing, chemical processing, power generation, and water treatment. They are particularly suitable for use in applications where high temperatures, high pressures, and corrosive fluids are present. Metal-seated ball valves are also used in industries where product contamination must be minimized, such as in the pharmaceutical and food industries.

Selection and Installation:

When selecting a metal-seated ball valve, it is important to consider the specific application requirements, including fluid type, pressure, temperature, and flow rate. It is also important to select the appropriate valve size and class to ensure reliable and efficient performance. Proper installation is critical to ensuring the long-term performance of metal-seated ball valves. The valves should be installed in accordance with manufacturer specifications and industry standards.

Conclusion:

Metal-seated ball valves are a reliable and durable solution for shut-off valve applications in harsh and demanding environments. They offer excellent sealing performance, high temperature and pressure resistance, and long service life. When selecting and installing metal-seated ball valves, it is important to consider the specific application requirements and follow manufacturer specifications and industry standards.

FAQs:

- What are metal-seated ball valves used for? Metal-seated ball valves are used for shut-off valve applications in harsh and demanding environments, including oil and gas processing, chemical processing, power generation, and water treatment.

- What materials are used to manufacture metal-seated ball valves? Metal-seated ball valves are made from a variety of materials, including stainless steel, carbon steel, and exotic alloys such as Inconel and Hastelloy.

- What are the advantages of using metal-seated ball valves? Metal-seated ball valves offer high temperature and pressure resistance, excellent sealing performance, and long service life. They are also less prone to leakage and require less maintenance than other types of valves.