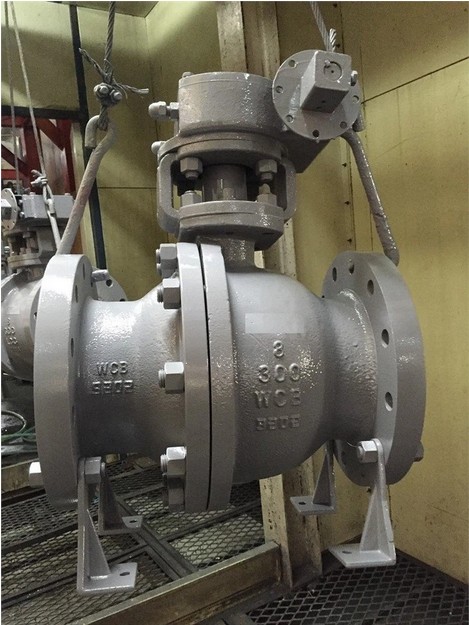

Casted Floating Ball Valve

Cast Floating Ball Valve Description

The Casted Floating Ball Valve is a type of valve used in various industries, including petroleum, chemical, power station, metallurgy, light industry, natural gas, sewage treatment, and municipal environmental protection. The valve is designed to cut off, distribute and change the flow direction of the medium in the pipeline. In this article, we will provide a comprehensive overview of the Casted Floating Ball Valve, including its design features, product range, materials, and design standards.

The Casted Floating Ball Valve boasts a compact and lightweight design, with a simple structure and a ball that can freely float, guaranteeing a secure seal. This valve operates by utilizing a ball with a circular hole as its opening and closing component, which is rotated by the stem to complete the opening and closing action, rotating 0 to 90 degrees around the center of the stem. With the ability to quickly switch and cut off the pipeline media by simply turning 90 degrees, it is an efficient and reliable choice for various industries.

Technical Specifications

| Specification | Description |

|---|---|

| Sizes | 1/2 to NPS 8 |

| Pressure Class | Class 150 to 2500 |

| Casting Materials | A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2 |

| Diameter | Full or reduced |

| End connections | RF, RTJ, BW or PE |

| Body design | Side entrance, welded |

| Anti-static device | Included |

| Blowout prevention | Rod included |

DESIGN STANDARD

Design and manufacture: API 6D, API 608 and ISO 17292

Face-to-face testing: API 6D, ASME B16.10

End connection: ASME B16.5

Test and inspect:o API 6D and API 598

Fire safety design: API 6FA and API 607

Also available: NACE MR-0175, NACE MR-0103, ISO 15848

Advantages of Casted Floating Ball Valve

The Casted Floating Ball Valve has several advantages over other types of valves. Firstly, it is small in size and lightweight, making it ideal for use in tight spaces. Secondly, it has a simple structure, with a ball that has a free-floating function, ensuring a good seal. Thirdly, the ball valve has a circular hole as the opening and closing member, allowing for rapid switching and a compact structure. Finally, by rotating the ball 0 to 90 degrees, the valve can be opened or closed, making it easy to cut off the pipeline media.

- Low Maintenance: One of the most significant advantages of a Casted Floating Ball Valve is that it requires minimal maintenance. The design of the valve means that there are no mechanical parts that need regular maintenance or lubrication.

- High Pressure and Temperature Tolerance: Casted Floating Ball Valves are designed to withstand high pressure and temperature, making them ideal for use in industrial applications that require these characteristics.

- Tight Seal: The design of a Casted Floating Ball Valve allows for a tight seal, even under high pressure. This tight seal ensures that there is no leakage of fluid, which is crucial in industrial applications where any leakage can cause significant damage.

- Versatility: Casted Floating Ball Valves can be used in a wide range of applications, including oil and gas, chemical processing, power generation, and water treatment. This versatility makes them an excellent choice for a range of industrial needs.

Applications of Casted Floating Ball Valve

Casted floating ball valves are used in a wide range of applications in the oil and gas industry. They are typically used to regulate the flow of fluids in pipelines and tanks, but they can also be used in other applications, such as:

- Oil and gas production: Casted floating ball valves are used in the production of oil and gas to control the flow of fluids and gases in the wellbore.

- Refining: Casted floating ball valves are used in refining processes to control the flow of fluids in various stages of the process.

- Storage: Casted floating ball valves are used in storage tanks to regulate the flow of fluids in and out of the tank.

- Transportation: Casted floating ball valves are used in pipelines to control the flow of fluids as they are transported from one location to another.

Why choose Fluid-Valves

we use the highest quality materials and manufacturing processes to produce our casted floating ball valves. We also offer a wide range of sizes and pressure ratings to ensure that our valves meet the specific needs of our customers. Additionally, our valves are designed to operate under extreme conditions, such as high temperatures and pressures, making them ideal for use in the oil and gas industry.

- What Are The Problems With Installing Stainless Steel Ball Valves?

- Pneumatic Actuated Gate Valve

- Segment Ball Valve: Applications and Advantages in Fluid and Gas Control Industries

- Maintenance Of Idle Valves

- The Importance Of Air Source Quality Of Pneumatic Valves

- How to Check the Performance of the Valve Before Leaving the Factory