Triple Eccentric Butterfly Valve

Introduction

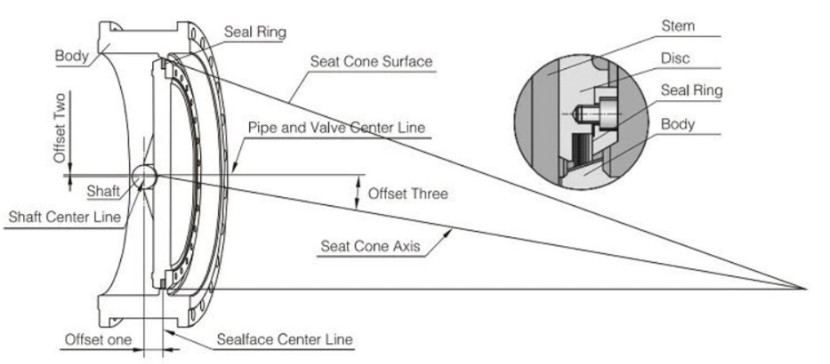

The valve body and valve seat of the tri-eccentric hard sealing butterfly valve are combined components. The valve seat sealing surface layer is built up with a weld of corrosion-resistant alloy material. The tri-eccentric design features the centerline of the shaft offsetting the centerline of the sealing surface, with the shaft centerline slightly deviating from the centerline of the pipeline. The centerline of the valve body sealing face (oblique circular cone) and the centerline of the pipeline form an angle of β.

The multi-layer sealing ring is made of soft and hard laminated sheet metal, providing the advantages of both metal hard seals and soft seals. It guarantees zero leakage sealing performance in both low and high temperatures.

Technical Specifications:

| Description | Specification |

|---|---|

| Sizes | NPS 3 to NPS 80 |

| Pressure Class | Class 150 to 600 |

| Casting Materials | A216 WCB, WC6, WC9, A350 LCB, A351 CF8, CF8M, CF3, CF3M, A995 4A, A995 5A, A995 6A |

| Other Materials | Alloy 20, Monel, Inconel, Hastelloy |

| End Connections | Wafer, Lugged, RF or BW |

Design Standard

Design & manufacture according to API 609

Face-to-face according to ASME B16.10

End Connection according to ASME B16.5 or B16.47 (Wafer, Lugged, Flange), ASME B16.25 (BW)

Test & inspection according to API 598

Also available per NACE MR-0175, NACE MR-0103

Advantages

The Triple Eccentric Butterfly Valve offers several advantages over other valves, including:

- Tight sealing: The valve’s design ensures that the disc is always in contact with the seat, providing a tight seal that prevents leakage.

- High pressure and temperature capabilities: The valve can handle high pressure and temperature without compromising its sealing capabilities.

- Low torque: The offset stem design reduces the torque required to operate the valve, making it easy to open and close.

- Low maintenance: The valve’s design reduces wear and tear, resulting in low maintenance costs over time.

Applications

The Triple Eccentric Butterfly Valve is suitable for a wide range of applications, including:

- Oil and gas industry: The valve is ideal for controlling the flow of crude oil, natural gas, and other hydrocarbons.

- Power generation: The valve’s high-pressure capabilities make it suitable for use in power generation plants.

- Water treatment: The valve’s tight sealing capabilities make it ideal for controlling the flow of water and wastewater.

- Chemical industry: The valve is suitable for controlling the flow of chemicals and other hazardous materials.

Benefits

The Triple Eccentric Butterfly Valve offers several benefits, including:

- Improved performance: The valve’s design ensures that it operates smoothly, providing improved performance over time.

- Increased safety: The valve’s tight sealing capabilities reduce the risk of leakage, increasing safety in the workplace.

- Cost-effective: The valve’s low maintenance requirements and long lifespan make it a cost-effective option over time.

Conclusion

The Triple Eccentric Butterfly Valve is an advanced version of the traditional butterfly valve. Its unique design provides several advantages over other valves, including tight sealing, high-pressure capabilities, low torque, and low maintenance requirements. The valve is suitable for a wide range of applications, including the oil and gas industry, power generation, water treatment, and the chemical industry. Proper installation is crucial to ensure that the valve operates effectively.