How Floating Ball Valves Work

Floating ball valves are a type of ball valve that controls the flow of liquids in pipelines. This valve features a floating or suspended ball that moves due to the pressure to control the flow. This article will discuss how a floating ball valve works and its applications.

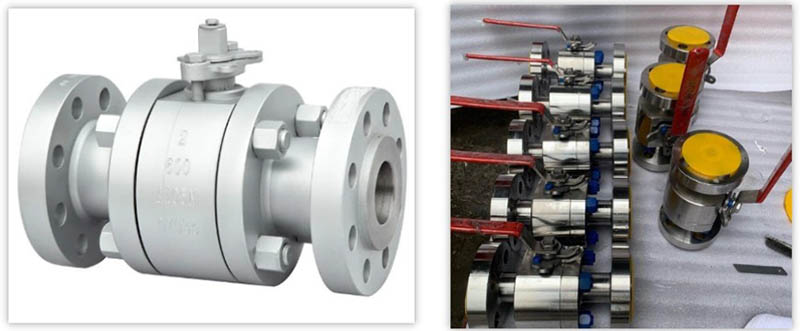

What Is a Floating Ball Valve?

A floating ball valve works by sandwiching a hollow ball between two cupped seats. The ball moves upstream when onstream pressure increases, and when the pressure drops, the ball moves downstream. The resulting seal prevents the liquid from leaking out. This valve is typically operated by a lever, gear, or pneumatic/hydraulic actuator. Floating ball valves are used in various applications to control the flow of a fluid.

The Working Principle of a Floating Ball Valve

A ball contains a hole in the center, which serves as the flow opening when the cross-section of the fluid flow path and the bore are coplanar. If the two are not coplanar, flow is throttled. Floating ball valves may consist of a solid ball with a consistent opening diameter throughout the structure. This makes fluid flow through the valve smooth and steady. However, a floating ball valve is most common in applications where the pressure is low. It is suited for a range of fluids, including gases and liquids. But, it cannot be used when the pressure on the upstream side is high because the ball directly absorbs the fluid’s gravity.

The operating mechanism of a floating ball valve is simple. The seat is connected by a stem while the ball is freely suspended. When the actuator is pressed, the stem moves, thereby creating pressure that allows the ball to move towards the seal and close the flow. The upstream seat acts as a secondary seal. A floating ball valve uses a seat that holds the ball in place while it floats in the valve body. As a result, downstream pressure pushes the ball against the downstream seat and forms a leak-tight seal.

Advantages of Floating Ball Valves

Floating ball valves have one common advantage over trunnion-mounted valves. The floating ball is more compact and lightweight than the trunnion-mounted valve, so it can be used in smaller projects. Floating ball valves can be used for either one-way or bi-directional shut-offs. They also provide a low-pressure solution. And because they can be easily turned 90 degrees, they’re an excellent choice for low-pressure projects.

In conclusion, floating ball valves have a variety of applications due to their versatility, lightweight, and reliability. They are used to control the flow of liquids in pipelines, and their working principle is simple. They rely on a floating ball that moves due to the pressure to control the flow. Floating ball valves are an excellent choice for low-pressure projects and can be used for either one-way or bi-directional shut-offs.

- Metal Seated Ball Valve

- Pressure Seal Bonnet Globe Valve

- General Requirements For Common Materials Of National Standard Valves

- How to check the performance of the valve before leaving the factory

- “Optimizing Efficiency and Safety: The Benefits of Casted Trunnion Ball Valve Design”

- Electric Actuated Ball Valve