Rack & Pinion Pneumatic Actuator

Introduction

Rack and pinion pneumatic actuators are widely used in industrial applications to control valves due to their durability, reliability, and ease of use. These actuators have a double rack and pinion design and a compact body, making them suitable for double-acting and spring-return models. They are made of hard-anodized aluminum for corrosion and wear resistance, and feature adjustable travel stops and an anti-blowout drive pinion. The NAMUR air connection can be easily installed with a solenoid valve. These actuators provide precise control over valve position, allowing for accurate regulation of fluid flow. They are ideal for use in process control, chemical processing, petroleum refining, water treatment, power generation, and food and beverage processing.

Features

- Can be mounted directly to a valve or via a bracket.

- Conforms to the European and International Standard EN ISO 5211 for preferred dimensions.

- Features a double rack and pinion design.

- The compact body design is used for both double acting and spring return models.

- The aluminum body is hard anodized internally and externally for corrosion and wear resistance.

- Includes adjustable travel stops.

- Safe end cover bolting requires no special tools.

- Includes an anti-blowout drive pinion.

- The Namur air connection can be easily mounted with a solenoid valve.

- Features a parallel and diagonal, double square (star) drive.

- Travel adjustment is possible at each end with an allowance of ±5°.

- Easy field conversion between double acting and spring return models.

Technical Specifications:

| Torque | Spring return 3.4 – 2442 Nm |

|---|---|

| Operating medium | Air (dry or lubricated) |

| Travel adjustment | (at each end) ±5° |

| Temperature | Standard -20°C to +80°C |

| Low temp. -40°C to +80°C | |

| High temp. -15°C to +150°C | |

| Air supply pressure | 2.5 bar (36 PSI) to 8 bar (116 PSI) |

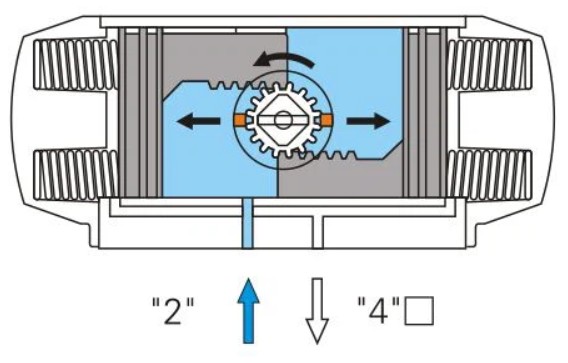

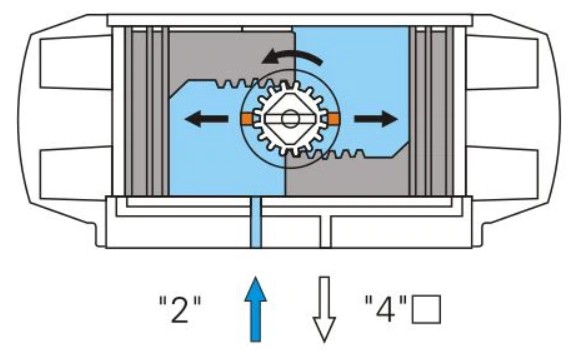

Spring return operation function (standard rotation) TOP view:

● Air supplied to Port 2 forces the pistons apart and toward the actuator end caps, compressing the springs with the exhaust air existing at Port 4, a counter clockwise rotation is achieved.

● On loss of air pressure (air or electric failure) at Port 2 allows the springs to force the pistons together with the exhaust air exiting at Port 2, a clockwise rotation is achieved.

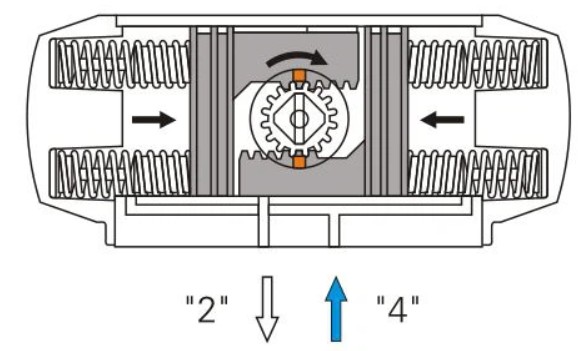

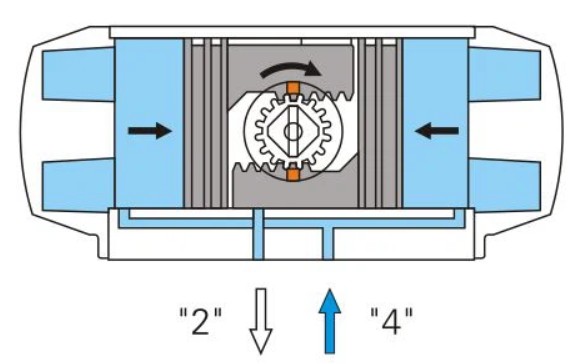

Double acting operation function (standard rotation) TOP view:

● Air supplied to Port 2 forces the pistons apart and towards the actuators end caps, with the exhaust air exiting at Port 4, a counter-clockwise rotation is achieved.

● Air supplied to Port 4 forces the pistons together with exhaust air exiting at Port 2, a clockwise rotation is achieved.

Advantages

Rack and pinion pneumatic actuators offer several advantages over other types of actuators. They are compact, lightweight, and easy to install, making them ideal for use in tight spaces. They are also highly durable and resistant to wear and corrosion, making them suitable for use in harsh environments. Additionally, they are energy-efficient, requiring less power to operate than other types of actuators.

Applications

Rack and pinion pneumatic actuators are commonly used in a variety of industrial applications, including:

- Process control

- Chemical processing

- Petroleum refining

- Water treatment

- Power generation

- Food and beverage processing

Benefits

Rack and pinion pneumatic actuators offer several benefits to industrial users. They are highly reliable and require minimal maintenance, reducing downtime and increasing productivity. They are also easy to operate and can be remotely controlled, making them ideal for use in hazardous or hard-to-reach areas. Additionally, they offer precise control over valve position, allowing for accurate regulation of fluid flow.

Installations

Installing a rack and pinion pneumatic actuator is a straightforward process. The actuator can be mounted directly to the valve or via a bracket. The actuator conforms to European and International Standard EN ISO 5211, preferred dimensions. The actuator has adjustable travel stops, a safe end cover bolting requiring no special tools, and an anti-blow-out drive pinion. The Namur air connection can be easily mounted with a solenoid valve. Parallel and diagonal, double square(star) drive, and travel adjustment (at each end) ±5°. The compact design of the actuator allows for easy field conversion between double-acting and spring-return models.

Q&A

Q: What is the torque range of the spring-return model? A: The torque range of the spring-return model is 3.4 – 2442 Nm.

Q: What is the operating medium of the actuator? A: The operating medium of the actuator is air (dry or lubricated).

Q: What is the temperature range of the actuator? A: The temperature range of the actuator is standard -20°C to +80°C, low temp. -40°C to +80°C, and high temp. -15°C to +150°C.