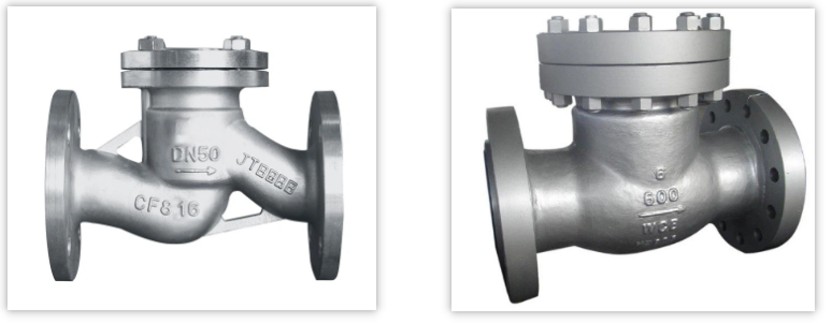

Lift Check Valve

Introduction

The seat design of a piston check valve is similar to that of a globe valve, with a piston for the disc. A lift check valve has a dashpot made of a cylinder and piston that provides protection during application.

These valves are typically used with angle and globe valves in piping systems that experience periodic changes in flow direction. They are also suitable for high-pressure applications with high flow velocity, and can be installed in both vertical and horizontal pipelines with upward flow. Lift check valves are commonly used in air, water, and steam systems. Different dimensions of piston check valves can be chosen in F-V.

Technical Specifications:

| Description | Specification |

|---|---|

| Sizes | NPS 2 to NPS 48 |

| Pressure Class | Class 150 to 300 |

| Casting Materials | A216 WCB, WC6, WC9, A350 LCB, A351 CF8, CF8M, CF3, CF3M, A995 4A, A995 5A, A995 6A |

| Other Materials | Alloy 20, Monel, Inconel, Hastelloy |

| Bore Type | Full or Reduced |

| End Connections | RF, RTJ, SW, BW, NPT, FNPT |

| Bonnet Type | Bolted Bonnet, Welded Bonnet or Pressure Seal Bonnet |

Design Standard

Design & manufacture according to API 6D, BS 1868

Face-to-face according to ASME B16.10

End Connection according to ASME B16.5 (RF & RTJ), ASME B16.25 (BW)

Test & inspection according to API 598

Also available per NACE MR-0175, NACE MR-0103

Advantages of the Lift Check Valve

The lift check valve offers several advantages over other types of check valves. Firstly, it has a higher flow rate due to the valve disc moving out of the flow path when the fluid flows, allowing for a larger flow area. Secondly, it has a lower pressure drop, which means that less energy is required to operate the valve.

Another advantage of the lift check valve is that it is less prone to causing water hammer, a phenomenon that occurs when the fluid in a pipe is forced to change direction suddenly, creating a pressure wave that can damage the pipe or other components in the system. Due to the lift check valve’s slower closing speed, it is less likely to cause water hammer than other types of check valves.

Applications of the Lift Check Valve

The lift check valve is a commonly used component in a variety of applications, such as water and wastewater treatment, oil and gas production, and chemical processing. In water and wastewater treatment plants, lift check valves prevent backflow and protect pumps from damage. In oil and gas production, they prevent the reverse flow of fluids in pipelines, which can damage equipment and create safety hazards. In chemical processing, lift check valves prevent the accidental mixing of incompatible fluids, which can cause dangerous reactions.

Q&A about the Lift Check Valve

Q: How does the lift check valve work? A: A disc inside the valve moves up and down in response to changes in fluid pressure. If the pressure on the upstream side is greater than the pressure on the downstream side, fluid can flow through the valve. If the pressure on the downstream side is greater, the disc moves down and blocks the flow of fluid.

Q:What materials are lift check valves made of?

A: Lift check valves can be made of a variety of materials, depending on the application. Common materials include stainless steel, bronze, and PVC.

Q: Can lift check valves be used in high-pressure applications?

A: Yes, lift check valves can be used in high-pressure applications. However, it is important to select a valve that is designed to withstand the specific pressure and temperature conditions of the application.

Conclusion

The lift check valve is an important component in many fluid systems, providing reliable and efficient flow control. Its advantages over other types of check valves make it a popular choice for a variety of applications. If you have any questions about lift check valves or need help selecting the right valve for your application, be sure to consult with a qualified valve expert.