“Improve Efficiency with the Lightweight Forged Floating Ball Valve”

Valves are a fundamental part of many industrial processes, but they can also be a source of hassle and frustration. Heavy valves can make installation and maintenance a cumbersome task, and their bulk can also impact performance. Fortunately, there is now a solution to this problem. The Forged Floating Ball Valve is a lightweight option that can make a significant difference in your system’s efficiency. Keep reading to learn more.

o

o

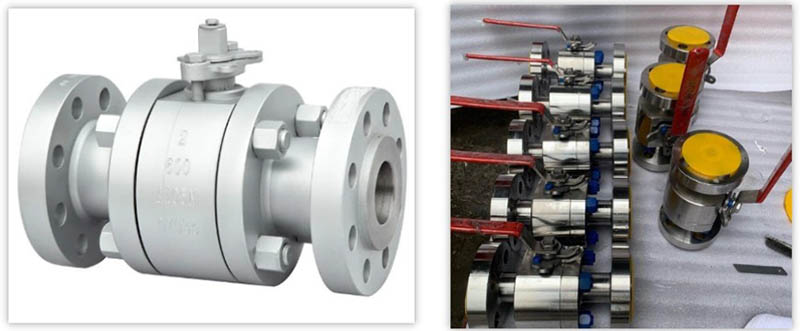

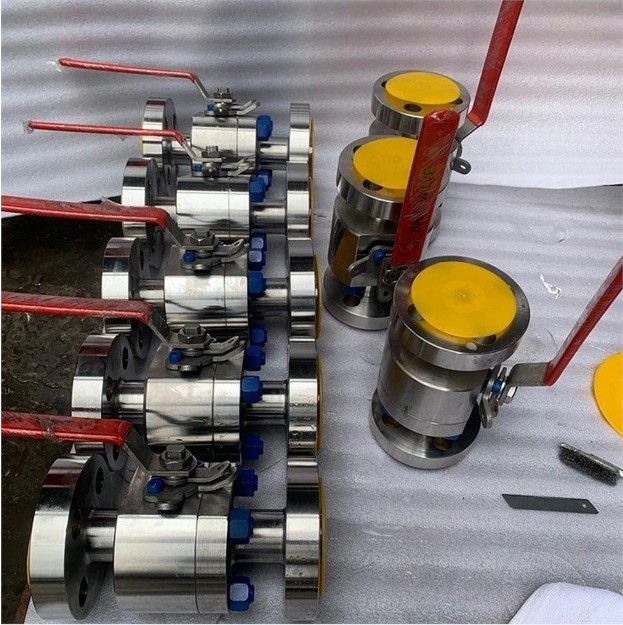

Introducing the Forged Floating Ball Valve

The Forged Floating Ball Valve is a ball valve designed to float in the pipeline. It is made from forged materials that make it exceptionally durable and resistant to wear and tear. The valve’s unique design makes it suitable for use in a range of applications, including oil and gas, chemical processing, and water treatment plants. Its floating ball design allows it to operate smoothly, providing a tight seal that minimizes leakage and allows for accurate flow control.

Say Goodbye to Heavy Valves with This Lightweight Solution

One of the most significant advantages of the Forged Floating Ball Valve is its weight. Unlike traditional valves, which can be heavy and bulky, this valve is lightweight, making it easier to install and maintain. Its compact size also means that it takes up less space in your system, which can be an important consideration in cramped or busy environments. That, combined with its long service life, makes it a cost-effective option for businesses looking to optimize their operations.

Enjoy Improved Efficiency with the Forged Floating Ball Valve

The Forged Floating Ball Valve’s lightweight design also has significant performance benefits. Its floating ball design means that it requires less force to operate, reducing the risk of damage to the valve and pipeline. Additionally, the reduced pressure drop across the valve helps improve the efficiency of your system, reducing energy costs and improving overall performance. All of these factors make the Forged Floating Ball Valve an excellent choice for businesses looking to streamline their processes and optimize their operations.

How to Install the Forged Floating Ball Valve in Your System

Installing the Forged Floating Ball Valve is a straightforward process that requires minimal downtime. First, ensure that the valve is the correct size and specification for your system. Then, follow the manufacturer’s instructions to install the valve, taking care to ensure that it is properly secured and aligned. Once installed, the valve should be checked regularly to ensure that it is operating correctly.

Key Features of the Forged Floating Ball Valve You Need to Know

The Forged Floating Ball Valve is designed with several key features that set it apart from traditional valves. These include its lightweight design, which makes it easy to install and maintain, and its floating ball design, which provides a tight seal and accurate flow control. The valve is also highly durable, thanks to its forged construction, and is suitable for a range of applications, including oil and gas, chemical processing, and water treatment plants.

Float Your System with Confidence Using the Forged Floating Ball Valve

The Forged Floating Ball Valve is an excellent option for businesses looking to improve the efficiency of their systems while reducing costs and improving performance. Its lightweight design, durability, and accuracy make it a top choice for a range of industries, and its ease of installation and maintenance mean that you can start seeing results quickly. So why wait? Float your system with confidence using the Forged Floating Ball Valve today!

Looking for a way to lighten up your system without sacrificing quality or performance? Look no further than the Forged Floating Ball Valve! This innovative valve is the perfect solution for those who need to reduce weight and increase efficiency without compromising on function. With its advanced design and high-quality materials, the Forged Floating Ball Valve is sure to keep your system floating smoothly and efficiently for years to come. So why wait? Float your system today with the Forged Floating Ball Valve!