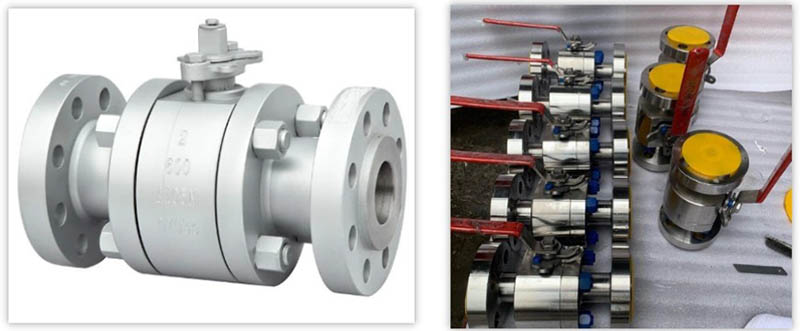

Forged Floating Ball Valve

Introduction

The Forged Floating Ball Valve is buoyant, allowing it to displace and press against the outlet end’s sealing surface when pressure from the medium is applied, ensuring a sealed outlet end. This valve design is small, lightweight, simple, and offers good sealing properties, making it a popular choice for low and medium pressure ball valves.

The Forged Floating Ball Valve has the same diameter as the pipe diameter, resulting in low flow resistance and high flow capacity. Additionally, the valve has a lowered stem, which eliminates the risk of the stem coming through and ensures safety during use. Due to its compact structure and light weight, it is considered the most reasonable valve structure for low temperature media systems.

Technical Specifications:

| Specification | Description |

|---|---|

| Sizes | NPS 1/2 to NPS 8 |

| Pressure Class | 150 to 2500 |

| Forged Materials | A105, A182 F304, F304L, F316, F316L, F51, F53, A350 LF2, LF3, LF5 |

| Other Materials | Monel, Inconel, Hastelloy |

| Bore | Full or Reduced Bore |

| Connection | RF, RTJ, or BW |

| Entry Design | Side entry, welded body design |

| Anti-Static | Anti-Static Device |

| Anti-Blow out | Anti-Blow out Stem |

| Extended Stem | Cryogenic or High Temperature Extended Stem |

DESIGN STANDARD

- Design & manufacture according to API 6D, API 608, ISO 17292

- Face-to-face according to API 6D, ASME B16.10

- End Connection according to ASME B16.5

- Test & inspection according to API 6D, API 598

- Fire safe design according to API 6FA, API 607

- Also available per NACE MR-0175, NACE MR-0103, ISO 15848

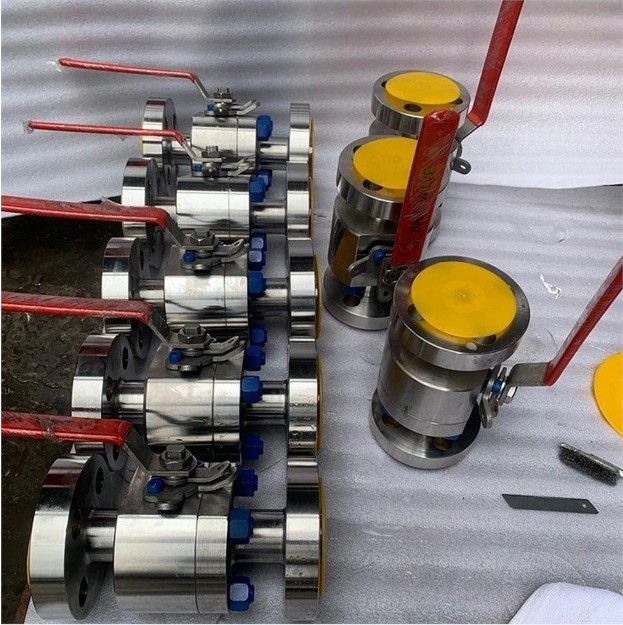

Types of Forged Floating Ball Valves

There are two main types of forged floating ball valves: trunnion mounted ball valves and floating ball valves. Trunnion mounted ball valves have additional support from a stem that is connected to the ball on both ends, while floating ball valves do not have a stem.

Trunnion mounted ball valves are typically used in high-pressure and high-temperature applications, while floating ball valves are used in low-pressure and low-temperature applications.

Advantages of Forged Floating Ball Valves

Forged floating ball valves offer several advantages over other types of valves, including:

- Durability: They are made from high-quality materials that can withstand harsh environments and corrosive fluids.

- High performance: They provide precise control over the flow of fluids, which improves system efficiency and reduces energy costs.

- Reduced maintenance: They require less maintenance compared to other types of valves, which saves time and money.

- Versatility: They can be used in a wide range of applications, from low-pressure to high-pressure and from low-temperature to high-temperature.

Applications of Forged Floating Ball Valves

Forged floating ball valves are used in various industries, including:

- Oil and gas industry: They are used to control the flow of crude oil, natural gas, and other hydrocarbons.

- Chemical industry: They are used to control the flow of corrosive chemicals and solvents.

- Power generation industry: They are used in power plants to control the flow of water, steam, and other fluids.

- Water treatment industry: They are used to control the flow of water and other fluids in water treatment plants.

Why choose Fluid-Valves

we use the highest quality materials and manufacturing processes to produce our casted floating ball valves. We also offer a wide range of sizes and pressure ratings to ensure that our valves meet the specific needs of our customers. Additionally, our valves are designed to operate under extreme conditions, such as high temperatures and pressures, making them ideal for use in the oil and gas industry.

- The Importance of Selecting the Right Steam Trap

- The Importance Of Air Source Quality Of Pneumatic Valves

- Pneumatic Actuated Gate Valve

- Ball Valve Specifications And Functions

- “Overview of Wedge Gate Valves: Components, Working Principle, Types, Applications, and Maintenance”

- How Does Y Strainer Work?