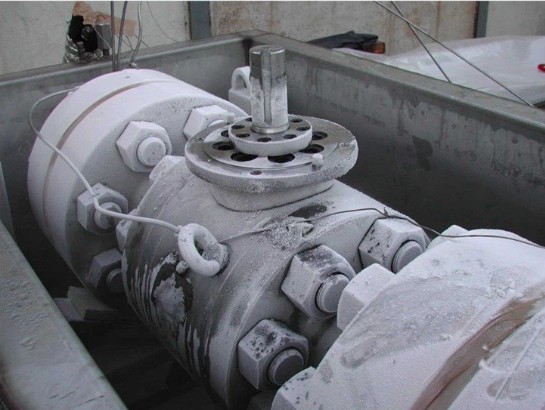

Cryogenic Ball Valve

Introduction to Cryogenic Ball Valves

Cryogenic Ball Valves are designed for applications in storage tanks, pipelines, and low pressure trailers for cryogenic fluids. These valves have a larger flow diameter, providing faster opening and closing times. Cryogenic Ball Valves can operate in a wide range of temperatures, from +120°C to -196°C, and are widely used in various industries, including LNG, pharmaceuticals, and wastewater treatment.

Technical Specifications:

| Specification | Description |

|---|---|

| Sizes | 1/22 to NPS 48 |

| Pressure Class | 150 to 2500 |

| Forged Materials | A105, A182 F304, F304L, F316, F316L, F51, F53, A350 LF2, LF3, LF5 |

| Casting Materials | A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2 |

| Other Materials | Monel, Inconel, Hastelloy |

| Bore | Full or Reduced |

| Connection | RF, RTJ, or BW |

| Entry Design | Side entry, or top entry |

| DBB | Double Block & Bleed (DBB),Double Isolation & Bleed (DIB) |

| Seat Injection | Emergency seat and stem injection |

| Anti-Static | Anti-Static Device |

| Anti-Blow out | Anti-Blow out Stem |

| Extended Stem | Cryogenic or High Temperature Extended Stem |

DESIGN STANDARD

Design & manufacture according to API 6D, API 608, ISO 17292

Face-to-face according to API 6D, ASME B16.10 OR MFG’s standard

End Connection according to ASME B16.5 (RF & RTJ), ASME B16.25 (BW)

Test & inspection according to API 6D, API 598

Fire safe design according to API 6FA, API 607

Also available per NACE MR-0175, NACE MR-0103, ISO 15848

Advantages of Cryogenic Ball Valves

One of the primary advantages of cryogenic ball valves is that they can operate effectively at extremely low temperatures, which makes them ideal for use in industries dealing with low-temperature fluids and gases. They are also easy to operate, require minimal maintenance, and have a long service life. Cryogenic ball valves are also versatile, as they can be used in a wide range of applications and are available in different sizes and configurations.

Applications of Cryogenic Ball Valves

Cryogenic ball valves are used in various industries, including aerospace, LNG, medical, and pharmaceuticals. In the aerospace industry, they are used in rocket engines and liquid fuel systems. In the LNG industry, cryogenic ball valves are used in storage tanks, liquefaction, and regasification facilities. In the medical and pharmaceutical industries, cryogenic ball valves are used in cryogenic storage tanks and transportation systems.

Design Considerations for Cryogenic Ball Valves

The design of cryogenic ball valves is critical to their performance in low-temperature environments. The valve body and components must be designed to prevent the formation of ice and prevent leaks. Cryogenic ball valves are designed with extended bonnets that provide extra insulation and prevent the valve stem from freezing.

Installation and Maintenance

Proper installation and maintenance of cryogenic ball valves are essential to their longevity and optimal performance. The valves must be installed according to the manufacturer’s instructions, with proper insulation to prevent ice formation. Regular maintenance, including cleaning and lubrication, is also necessary to ensure that the valve operates smoothly and effectively. It is also essential to inspect the valve regularly to detect any signs of damage or wear.

Safety Precautions for Cryogenic Ball Valves

Cryogenic ball valves must be handled with care and safety precautions to prevent injuries and accidents. Personnel should wear personal protective equipment (PPE), including cryogenic gloves, goggles, and face shields, when handling these valves. It is also essential to follow safety protocols for handling cryogenic fluids and gases, including proper ventilation, fire prevention measures, and emergency response plans.

Comparison with Other Types of Valves

Cryogenic ball valves offer several advantages over other types of valves, including gate valves, globe valves, and butterfly valves. They have a low-pressure drop, which reduces energy consumption and operating costs. They are also more reliable, with fewer leak points and a longer service life. In comparison to gate valves and globe valves, which have high friction losses, cryogenic ball valves have low friction losses, resulting in lower pumping costs.

Conclusion

In conclusion, cryogenic ball valves are critical components in industries dealing with low-temperature fluids and gases. They offer several advantages, including low-pressure drop, high reliability, and long service life. Cryogenic ball valves are available in different types, sizes, and materials, and their design and installation are critical to their performance. Safety precautions must be taken when handling cryogenic ball valves, and regular maintenance is necessary to ensure optimal performance. The future of cryogenic ball valves is promising, with advancements in technology and increasing demand in various industries.

- Forged Trunnion Ball Valve

- Understanding the Difference Between a Part 1 and Part 2 Float Valve

- Scotch Yoke Pneumatic Actuator

- Introduction Of Floating Pneumatic Ball Valve

- Understanding Y Strainers: Function & Importance

- Segment Ball Valve: Applications and Advantages in Fluid and Gas Control Industries