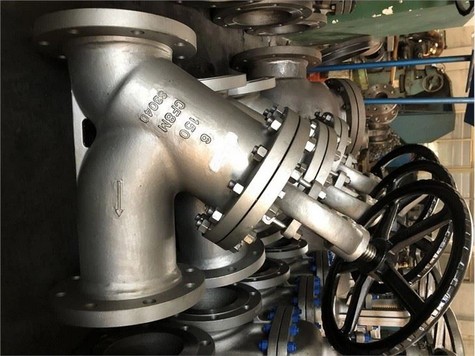

Y Type Globe Valve

Introduction to Y Type Globe Valve

The Y Type globe valve, also known as a Y type globe valve, is designed with a seat and stem angled approximately 45°C to the center of the pipeline, reducing flow resistance and making it ideal for applications requiring enhanced flow capacity and minimal leakage. It is commonly used to throttle flow in demanding operations in the oil and gas, chemical, and power industries. F-V offers a wide range of globe valves to suit your unique application needs, ensuring maximum efficiency and reliability. With its unique design, the Y type globe valve reduces the possibility of cavitation and erosion, making it a reliable and efficient choice for controlling fluid flow in various industries.

Technical Specifications:

| Description | Specification |

|---|---|

| Sizes | NPS 1/2 to NPS 48 |

| Pressure Class | Class 150 to 2500 |

| Casting Materials | A216 WCB, WC6, WC9, A350 LCB, A351 CF8, CF8M, CF3, CF3M, A995 4A, A995 5A, A995 6A |

| Other Materials | Alloy 20, Monel, Inconel, Hastelloy |

| End Connections | RF, RTJ, or BW |

| Stem Design | Outside Screw & Yoke (OS&Y), Rising stem |

| Bonnet Type | Bolted Bonnet or Pressure Seal Bonnet |

Design Standard

Design & manufacture according to BS 1873

Face-to-face according to ASME B16.10

End Connection according to ASME B16.5 (RF & RTJ), ASME B16.25 (BW)

Test & inspection according to API 598

Also available per NACE MR-0175, NACE MR-0103, ISO 15848, API 624

Advantages of Y Type Globe Valve

The Y Type Globe Valve has several advantages over other types of globe valves. These include:

- Smooth Flow: The valve’s Y-shaped body design allows the fluid to flow smoothly through the valve, reducing the pressure drop across the valve.

- Reduced Cavitation and Erosion: The valve’s design reduces the possibility of cavitation and erosion, which can damage the valve and the piping system.

- Easy Maintenance and Repair: The valve’s design allows for easy maintenance and repair, reducing downtime and increasing productivity.

- Versatility: The valve can be made of various materials, making it versatile and suitable for different types of fluids and applications.

Applications of Y Type Globe Valve

The Y Type Globe Valve is commonly used in a variety of industries such as petrochemicals, power generation, oil and gas, water treatment, chemical processing, pharmaceutical processing, food and beverage, and pulp and paper. Its unique Y-shaped body design allows for smooth flow, reduced cavitation and erosion, easy maintenance and repair, and versatility in material selection. The valve undergoes various tests and inspections to ensure its quality and safety, including hydrostatic and pneumatic testing, visual inspection, and non-destructive testing. Overall, the Y Type Globe Valve is a reliable and efficient choice for controlling fluid flow in various industries.

Benefits

Y Type Globe Valve has several benefits, including:

- Smooth Flow: The valve’s Y-shaped body design allows the fluid to flow smoothly through the valve, reducing the pressure drop across the valve.

- Reduced Cavitation and Erosion: The valve’s design reduces the possibility of cavitation and erosion, which can damage the valve and the piping system.

- Easy Maintenance and Repair: The valve’s design allows for easy maintenance and repair, reducing downtime and increasing productivity.

- Versatility: The valve can be made of various materials, making it versatile and suitable for different types of fluids and applications.

Frequently Asked Questions

Q: What is the purpose of a Y type globe valve? A: The purpose of a Y type globe valve is to regulate the flow of fluids or gases through a pipeline.

Q: What is the maximum pressure rating for the Y type globe valve? A: The Y type globe valve can have a maximum pressure rating of Class 2500.

Q: What materials are used to make the Y type globe valve? A: The Y type globe valve is typically made of materials such as cast iron, cast steel, stainless steel, or bronze.

Conclusion

Y Type Globe Valve is an essential component of many industrial processes. The valve’s Y-shaped body design, technical specifications, design standards, applications, benefits, and Q&S make it an ideal choice for controlling the flow of fluids in various industries. The valve’s advantages over other types of globe valves make it a popular choice among engineers and operators. If you are looking for a reliable and efficient globe valve, consider Y Type Globe Valve.

- Socket Welding Check Valves: A Comprehensive Guide

- “Improve Efficiency with the Lightweight Forged Floating Ball Valve”

- Efficient and Versatile: The Casted Floating Ball Valve for Industrial Applications

- How Swing Check Valves are Tested and Inspected: A Comprehensive Guide

- The Benefits of Casted Trunnion Ball Valves in Industrial Applications

- Principle of Valve Sealing